Introduce

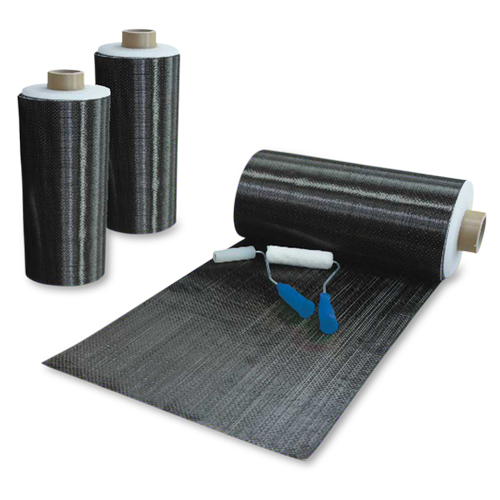

Description

This is an advanced new material to improve seismic and load-bearing capacity, and at the same time has a higher tensile strength than steel, has been used to repair and reinforce concrete structures since the 1990s. In recent times Japan is prone to earthquakes, and is largely carbon fiber.

Characteristic

– High strength steel reinforcement with tensile strength 10 times higher than steel

Reinforcement in less quantity than steel

Light weight: density is 1/5 of steel

– Not damaged by external factors such as water, bases, acids or ultraviolet rays

– Easy to apply in small areas due to completely manual application

– Outstanding construction ease

Specifications & Physics

Data item Carbon fiber mesh 200g Carbon fiber mesh 300g

Characteristics Unit Test value Test value Test method

Tensile Strength Gpa (kgf / cm2) 4.4 (44,867.5) 4.8 (48,946.4) ASTM D3039

Tensile Strength Module Gpa (kgf / cm2) 350.2 (3,571,046) 346.5 (3,533,317) ASTM D3039

Textile

UD (one direction) UD (one direction) KS L 2522

Warp type Carbon fiber type 12K Carbon fiber 12K

Weft / Tensile force G150 1/0 G150 1/0

Proportion Warp 6,4 9.6

Weft / Tensile Strength 5 3.5

Weight g / m2 200 ± 10 300 ± 10

Mesh width mm 500 500

Mesh thickness mm 0.11 ± 0.050 0.16 ± 0.050

Application

Highway bridge and railway bridge against earthquakes

Earthquake-proof columns, beams and walls

Repair and reinforcement of reinforced concrete deck

Repair and reinforcement of beams and panels, etc.

Repair and reinforcement of circular structures such as tunnels and cellars, etc.

Construction method

Surface repair & cleaning

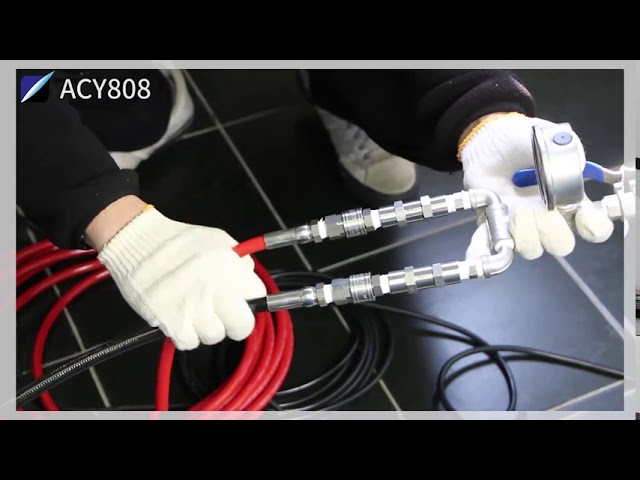

Remove all areas contaminated by debris, grease by grinding and repair cracks or damaged parts by epoxy resin injection (Grinding angle to radius R = 30mm).

Appropriate ambient temperature is from 10ºC to 35ºC.

Construction of the lining

Apply the primer primer several times to the place where the concrete surface will adhere to the carbon fiber.

(Standard amount of primer: 0.3kg / m2)

Curved surface control

Use epoxy putty on areas depth greater than 1mm.

Construction of surface plastic layer (first layer)

After the primer dries, roll or cover with a plastic coating to create adhesion (standard quantity: 0.5kg / m2)

Attach the carbon fiber plate

Attach the carbon fiber sheet to the concrete structure and rub the surface repeatedly with a rubber roller or table in the direction of the fiber. Make sure that there are no airbags inside the fiber sheet.

Applying the surface plastic layer (second layer)

Cover the surface of the fiberboard with plastic and allow the plastic to penetrate the fiber sheet by rubbing it repeatedly in the direction of the fiber (standard amount of plastic: 0.3 kg / m2). In the case of adding more sheets of yarn, repeat steps 4,5,6.

Maintenance

It takes 1 week for epoxy resin to fully harden at 20ºC and 2 weeks at 10ºC.

Surface finishing

Surface finishing with paint.