USES

MEMBRANIL are multi-purpose membranes for protected roofing & waterproofing applications subjected to different mechanical stresses and normal weathering conditions, Also recommended as a base layer in multi layer systems in various application.

MEMBRANIL membranes are particularly recommended for the following applications.

– Roofing or re-roofing works for sloped and flat protected roofs.

– Waterproofing of underground structures

– Waterproofing of wet areas, mechanical rooms and terraces.

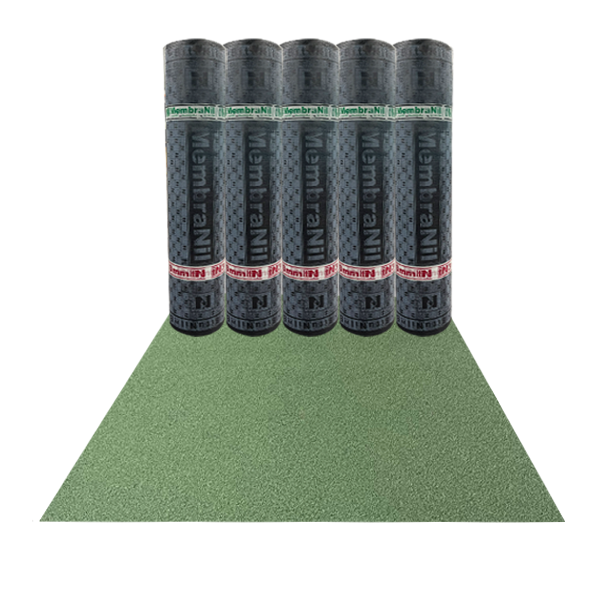

SURFACE FINISH

The lower surface of MEMBRANIL is laminated with a Polyethylene film while the upper surface is covered with one of the following surface finish materials:

– Fine Sand MEMBRANIL- S/E

– Polyethylene Film MEMBRANIL- E/E

APPLICATION

MEMBRANIL is usually applied by using a propane torch or a hot air generator as well as by mechanical fastening. It can also be applied using special adhesives in cold or hot applications. The substrate surface must be clean, dry, smooth, and free from any irregularities. According to the surface conditions, a coat of BituNil primer maybe required prior to the application of the membrane. MEMBRANIL can be applied to the substrate fully bonded, semi bonded or loose laid, and the method of adhesion to the substrate shall be decided according to the waterproofing system design. Side laps should be from 8-10 cm, while end laps should be from 12-15 cm. For more info on application refer to BituNil application guide.

STORAGE & HANDLING

MEMBRANIL rolls should be kept in an upright position in a flat, properly ventilated and sheltered storage area.

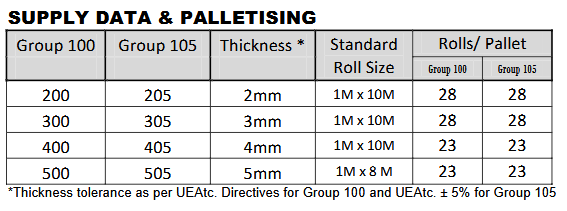

Loading Capacity: 20 pallets / Container

The above quantities are indicative only and may be subject to changes in order to comply with transport limitations according to the final destination of the product.

BituNil membranes are made of non-polluting substances, therefore are safe products during production, application and use.