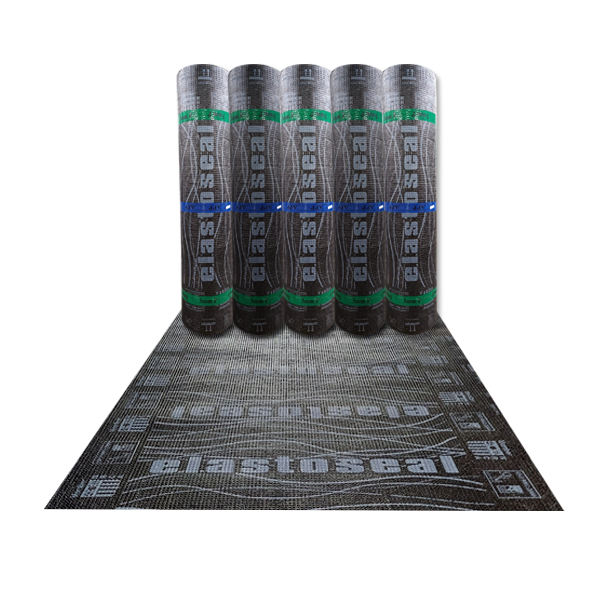

What is Elastoseal ?

Produced by the Modern Waterproofing Company, Elastoseal is a line of polymermodified bitumen waterproofing membrane of the highest quality.

Elastoseal is modified by APP and APAO, thus guaranteeing superior performance under various conditions.

ELASTOSEAL is reinforced with Spunbond Non-woven Polyester (P) which provides high mechanical properties.

Uses

ELASTOSEAL is a general purpose membrane, can be applied virtually anywhere where torch applied modified bitumen membranes subject to light to moderate mechanical stresses are specified, and normal low temperature performance is required.

ELASTOSEAL can be applied in:

• Single layer roofing system for normal use.

• Double layer roofing system combined with ELASTOSEAL fiberglass reinforced.

• Waterproofing of toilets & wet area inside buildings.

• Slab on grade.

ELASTOSEAL with Mineral Slated Finish is recommended for exposed roofing system (Unprotected) for Non-accessible roofs or roofs subject to low traffic conditions.

Advantages

ELASTOSEAL has been designed with special regard to providing clients with an excellent and versatile product line.

Advantages of ELASTOSEAL include:

• Easy to apply (by torch).

• High mechanical properties.

• Absolute impermeability to water pressure.

• Flexibility at low temperature up to -2c0

• Excellent high temperature performance.

• Excellent adhesion on any surface.

• High dimensional stability.

• Environmentally friendly.